Find Answers and General Information Quickly

The horizontal (x) axis of the graph represents the pixel number of the CCD line array. The vertical (y) axis represents the light intensity for the given pixel in arbitrary units. The graph therefore shows the direct measurement of the interference patterns focussed on the array. It is important to note that this is not the spectrum! However, some spectral information can be gained out of the interference pattern, e.g. if your laser is running single mode or if it there are any sidebands.

1. Minimum Input Energy

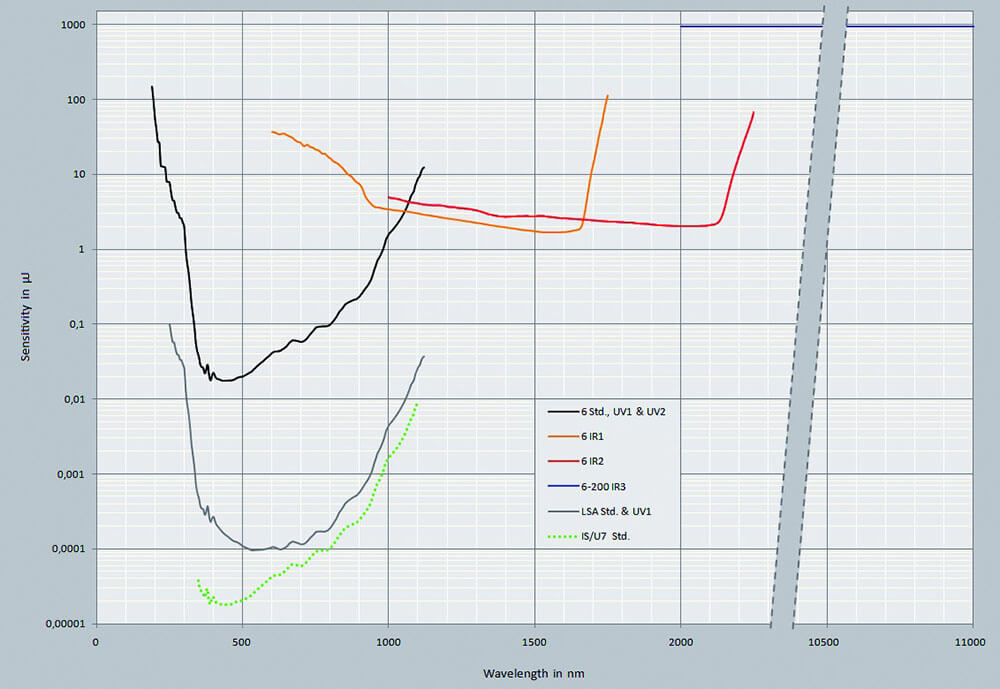

The minimum input energy required differs for the several wavelength ranges. Please see the graph below for sensitivity information of our products.

2. Maximum Input Energy/Damage Threshold

a) Fiber patch cords and connectors

Standard fiber optical patch cords and the FC/PC connectors can endure up to 300 µJ. Higher energies will most likely damage the fiber input.

b) Multichannel Switches

HighFinesse multichannel fiber switches use micro-mechanical technology which allows almost unlimited switch cycles, but limits the laser power the instrument can endure. To avoid damaging the multichannel fiber switch especially with short pulses, please use the wavelength meter in CW mode and use a long exposure time (at least > 100 ms). This way you can integrate over several pulses and keep the peak power low. The following limits should not be exceeded:

CW lasers: The limit is 5 mW for wavelength > 400 nm. For lasers with wavelength < 400 nm the limit is 0.5 mW. HighFinesse wavelength meters usually only need a few μW, this should be more than sufficient, even when transmission losses through the multichannel fiber switch are taken into account.

Pulsed lasers: For the average power of pulsed lasers, the same limits as for the CW case apply. Besides that, a maximum peak power during the pulse of 2 W (0.2 W for wavelength < 400 nm) should not be exceeded.

Note: 2 W peak power equals 2 μJ for 1000 ns pulses, 0.2 μJ for 100 ns pulses, and 0.02 μJ for 10 ns pulses! For measurements of short pulses please use long exposure times and integrate over several pulse trains to get the required power for a valid measurement. The average power of such a pulsed laser depends on the duty cycle D and is given by D × 2 W.

c) Wavelength Meters

The actual damage threshold of a HighFinesse wavelength meter is not relevant because it is not possible to enter the wavelength meter in a free-beam manner. Please be aware, that the CCD of a wavelength meter will be overexposed long before the damage threshold is reached. This means that the necessary input energy for a properly illuminated measurement will always lie far below the wavelength meter’s threshold.

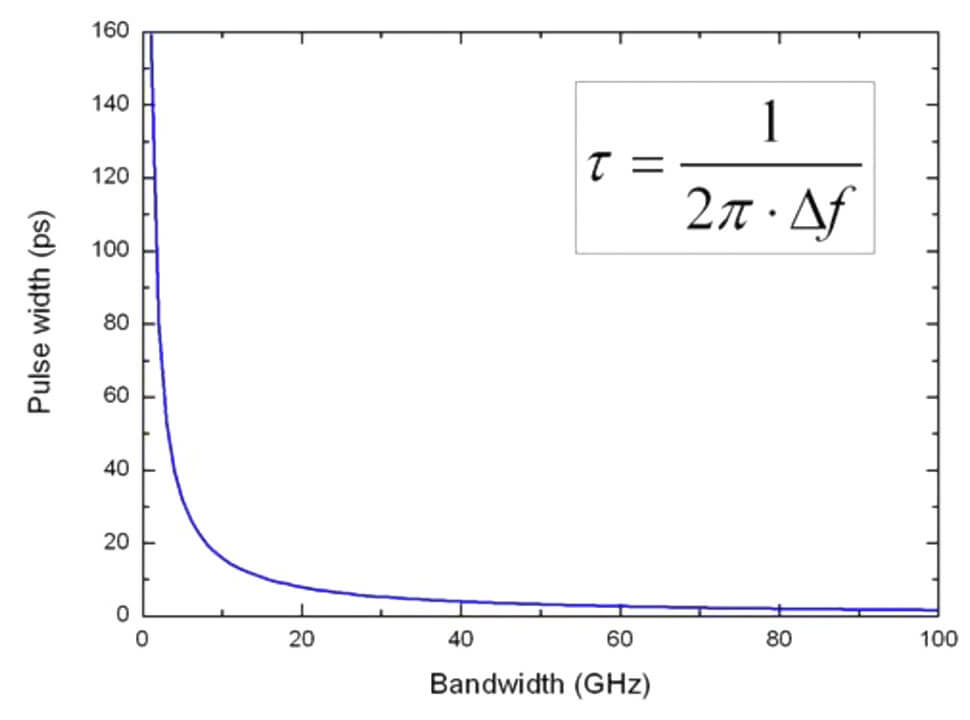

The shorter a laser pulse is, the broader the spectral width of this laser. Laser pulses shorter than 100 ps can only be measured by the D option (Diffraction grating) or our spectrometers.

The accuracy of the wavelength meter is determined by the length of the longest interferometer inside the optical unit. The longer the interferometer, the smaller the spectral width of the laser has to be. If the laser is broader than the “free spectral range” (FSR) of the interferometer, the interference vanishes and no signal can be analyzed.

The FSR can be found in the product description and in the datasheet brochure. Look at each wavelength meter type at the line “Fizeau-interferometers (Fine/wide mode)”. The upper limit for the spectral width of lasers which can be measured with each wavelength meter is roughly 30 % of the FSR. Please inquire with our service, in case your laser might exceed these limits. Or have a look at our spectrometers, which can measure broad lasers (LSA) and broad band spectra up to 600 nm (HDSA).

Also for each model (except WS5) there is, in addition to the standard “Fine Mode”, a so called “Wide Mode”. In this measurement mode the longest interferometer will be ignored for the calculation. For instance, the WS7-60 is able to measure lasers with a maximum spectral width of 8 – 12 GHz in Wide Mode. In normal or Fine Mode, only lasers with a spectral width smaller than 3 GHz can be measured.

FSR (Fine/Wide Mode)

WS5 – 100

WS6-600 – 16/100

WS6-200 – 16/100

WS7-60 – 8/32

WS7-30 – 4/32

WS8-10 – 2/20

WS8-2 – 2/20

Note: The maximum accuracy is limited by the linewidth of the laser. Typically the accuracy is a factor of 3 – 5 smaller than the laser linewidth. So, if the laser has a linewidth of 10 GHz, the highest accuracy obtainable is approximately 2 GHz.

Always make sure to use an FC/PC connector towards our wavelength meters and multichannel switches. Measurement results will suffer if FC/APC is used instead.

Multimode Fibers

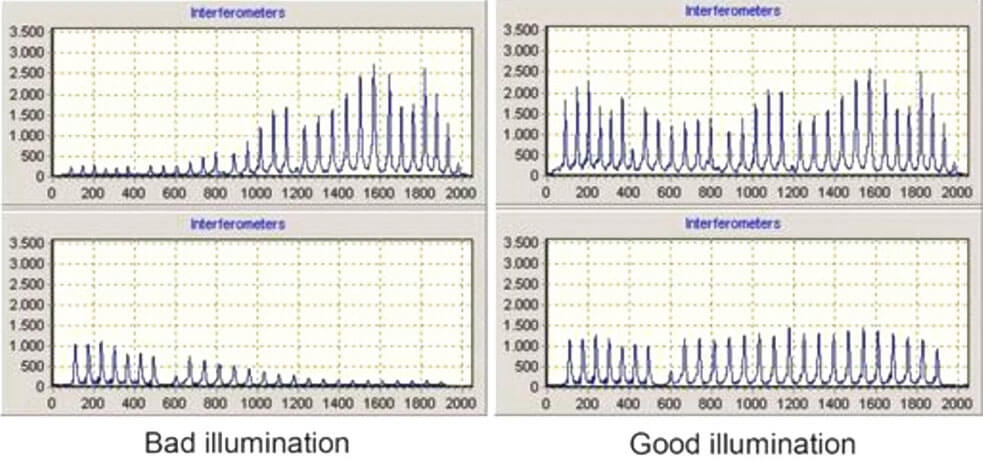

To ensure high accuracy for all measurements, please adjust the optical setup so, that the interferometers are illuminated evenly. Good illumination means the peaks have approx. 60 % of the screen height (at least 1000, better 2000) and the height does not vary by a factor of more than 2.

Singlemode Fibers

The same principle has to be followed while using singlemode fibers. Usually the height distribution of the peaks is more consistent due to the singlemode transmission. Should you use singlemode fibers below their cut-off, multimode effects will come into play and an even distribution has to be achieved for better accuracy.

HighFinesse offers help in the interpretation of interference patterns. For this we need a raw data recording (interferogramm and further device parameters) of the measurement of interest.

A Long Term Recording (LTR file) includes all measured values such as wavelength, pressure, and temperature time independently. It also contains some device information like interferogram data, used calibration and software settings.

No user information is stored.

Please read the next FAQ to know how a LTR-file is recorded.

Please read chapter 2 of your printed manual, run a measurement and make sure everything is adjusted well and the exposure time allows a quite good signal so that half of the interferometer charts is illuminated.

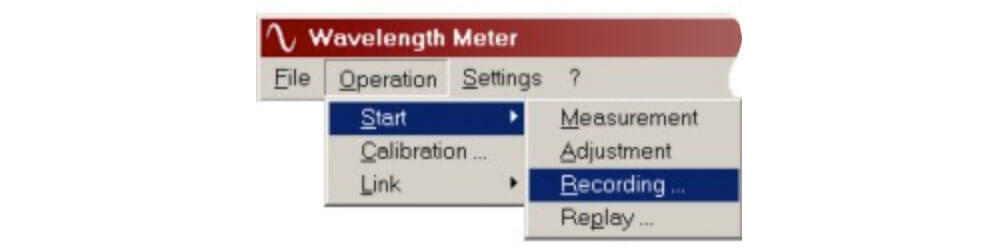

Stop the measurement and start the recording by selecting “Operation | Start | Recording ...” and choose a filename and location for the recording. Immediately after closing the dialog the recording will start and the measurements will be saved until you press “Stop”.

It is not necessary to produce very long recordings as the filesize is growing strongly with the measurement count. Usually up to 100 measurement points are more than enough. You may choose to record for a longer time to depict the phenomenon at hand.

Send this file along with these additional files:

- all *.ini

- all *.stn

- history.serial_of_wavemeter

- and complete folder "calibrations"

Attention:

You can find these files in the program folder of your device.

If you are using Windows Vista, Win7, Win8 or Win10, these files have been redirected to the virtual store. You can find this hidden folder usually at this place:

C:\

Users\

%USERNAME%\

AppData\

Local\

VirtualStore\

Program Files (x86)\

HighFinesse\

Wavelength Meter WS ...

Please copy and complete the folder path into the file explorer of your choice. Otherwise the Windows folder settings have to be changed to “Show hidden files, folders and drives” to see the hidden folders.

Most likely the multichannel switch is not actually switching channels.

1. Please check if all communication and power cables are connected. Some switches have an external power supply.

2. Check the software if the communication protocol settings are correct. Select SETTINGS | SWITCH SETTINGS | SWITCH PARAMETERS:

TTL (5pin LEMO): choose WLM TTL S

RS232: choose COM

USB: choose USB COM U

For COM-port connected switches check the COM-port settings as well. Ensure everything is plugged in and you chose the correct COM-port and baudrate +(usually 57600, however older versions use 9600).

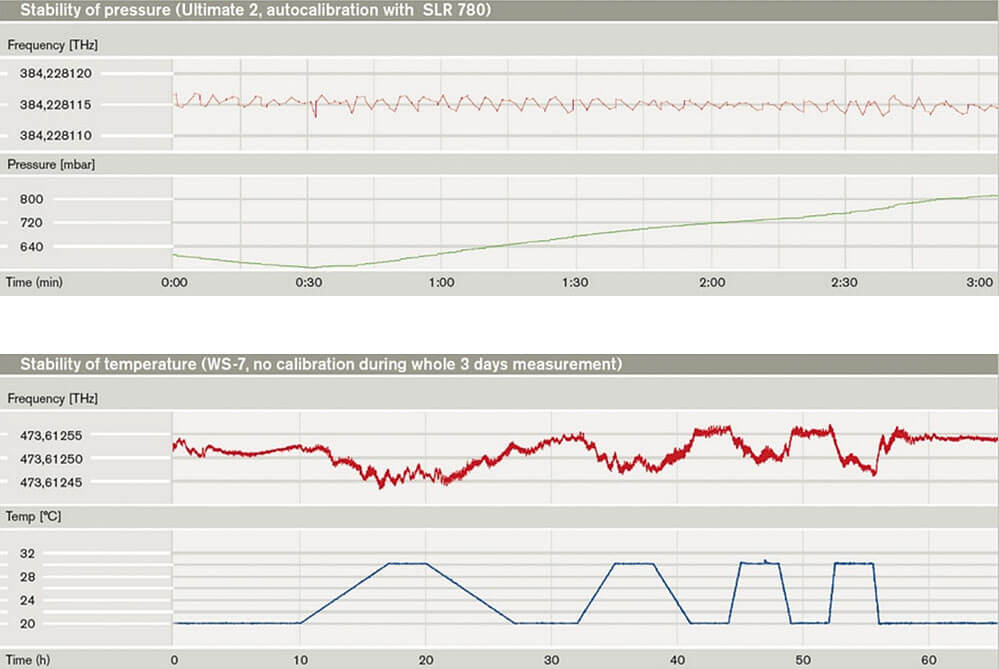

Pressure Stabililty

In the upper diagram above you can see a sample measurement of our WS-Ultimate series with an accuracy specification of ± 2 MHz. The measurement effectively is not influenced by the pressure change from ca. 560 to 800 mBar.

Temperature Stabililty

To achieve best results, the wavelength meter should reach a thermal equilibrium with its environment, before starting a measurement. Usually it is enough to keep it in the lab for 1 – 2 hours right before the measurement.

As the temperature of the interferometer is measured and considered in the calculation, slow temperature changes do not influence the accuracy.

In the lower diagram above you can see the temperature stability of our WS7. The wavelength meter was kept in a climate chamber for several hours while changing the temperature drastically. As long as the change is below approx. 2 °C/h, the temperature drift is compensated quite well.

Pulsed Mode (all wavelength meters)

All wavelength meters can measure cw and pulsed lasers.

In case a pulsed laser is coupled to any HighFinesse wavelength meter, it automatically detects incoming pulses and calculates the wavelength. It will handle any laser as quasi-cw, whose repetition rate exceeds the maximum measurement rate of the wavelength meter.

External Trigger Option (TTL)

This option allows to externally trigger the wavelength meter for pulsed measurements. This can be useful in several situations, e.g. when only every other pulse needs to be measured, low duty cycles, strong background radiation fills up the array with noise, or single pulses (pulse groups) need to measured at specific time sets. Two trigger modes are available. Both modes allow to define start and stop point of the measurement in a very specific way.

In mode 1 the TTL signal starts the read-out of the wavelength meter arrays. The measurement will only stop upon a second TTL signal.

In mode 2 the TTL signal starts the read-out of the wavelength meter arrays, which lasts for a user pre-defined period of time.

Note: For IR-III devices, please read the manual – or contact our customer service.

HighFinesse wavelength meters are known for their robust design due to not containing any moving parts. It is still necessary to re-calibrate the device within a suggested calibration period (see datasheet). Most of the wavelength meters have integrated calibration sources, that enable quick and easy calibration within a couple of seconds.

External calibration sources

Over time temperature and pressure drifts influence the whole calibration curve. If left uncalibrated high accuracy wavelength meter optics will possibly get shifted and tilted by temperature and pressure shifts. This can influence both the absolute and relative accuracy.

Those small anomalies can be detected and eliminated by storing calibration data of not only a single wavelength value, but also the whole interference pattern of all interferometers.

Note: The calibration data is saved in the installation folder of your PC. When the wavelength meter is moved to a different PC a new installation and calibration will be necessary. A transfer of the calibration data from one PC to the other is not advised.

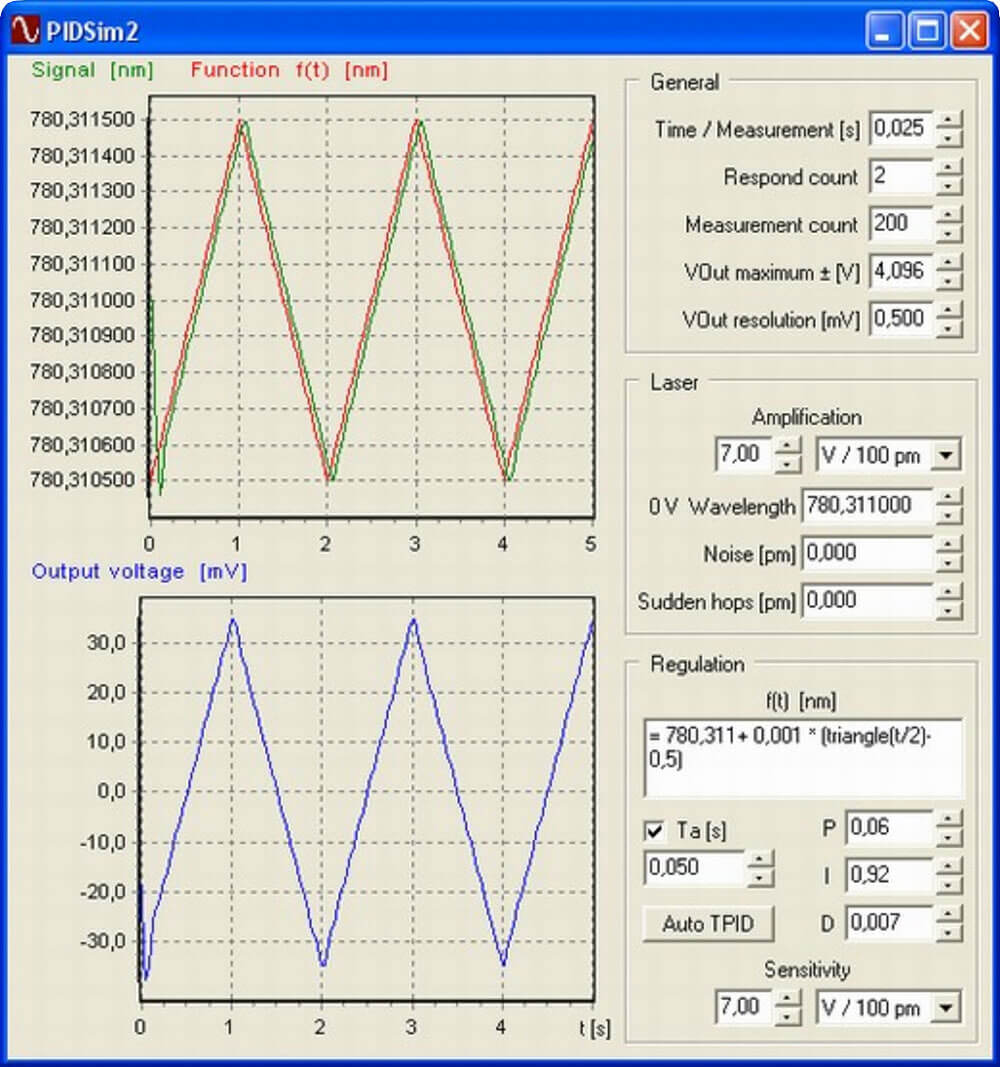

To find the right parameters and to optimize the PID-controller to have the most accurate and fastest feedback control of your laser can be a real challenge sometimes. We hereby describe a quick procedure finding the parameters P, I, D and the time constant Ta for the I- and D-calculation. This procedure is based on our PID-Simulator which estimates these parameters according to your setup- and laser-conditions.

First, you need to setup your Wavelength Meter:

Set an appropriate exposure time (the smaller the better). (e.g. 5 ms) Start the measurement and determine the repetition rate (simply type “RepetitionRate” in the “Start | Run...” dialog box). (e.g. 40 Hz)

Now, you need to know your laser:

Find a working range where the laser is operating mode hop free in a certain range. This working range must cover the wavelength range you want to regulate. Apply 0 V on the LC-output of thewavelength meter using the “Calibration”-tab in the laser control settings window and press “Send”. Which wavelength does the wlm display? (e.g. 780.311 nm)

Increase the output voltage step by step and observe the max. mode hop free range and the amplification V/nm.

Decrease the output voltage step by step and observe the max. mode hop free range and the amplification V/nm.

Now calculate the amplification (e.g. 7 V/100 pm)

It might be also necessary to limit the maximum/minimum voltage of the LC-output in order not to cause the laser to jump during the regulation (mode hop). Therefor set these values in the “Bounds”-tab in the laser control settings window.

Note: The “Test”-output voltage might be not available in older software versions. Then you need to disconnect the LC-cable and apply the desired voltage by an external power supply to find out the 0 V-wavelength and the amplification.

Run the » PID-Simulator:

You need to adjust the General- and Laser-settings to fit your experimental conditions:

General settings:

Time/Measurement = 1/Repetition Rate (e.g. 1/40 Hz = 25 ms = 0.025 s)

Response count = 2 (The PID gets an answer to its action after the next measurement shot, do not change this!)

Measurement count is only for displaying the function, it has no influence on the calculation (-speed).

V_out maximum = ± 4096 mV (this is the max. range the wlm can give out)

V_out resolution = 0.5 mV (14 bit resolution on max. range, do not change this!)

Laser settings:

Type in the amplification and 0 V-wavelength you determined above.

Noise and Sudden hops can be left \“0\” usually.

Regulation:

Formula: Use whatever you desire, within the mode hop free wavelength range (e.g. f(t) = 780.311+ 0.001 * (triangle(t/2)-0.5) to see how the laser reacts)

Ta, P, I and D, you can leave blank as these values are estimated automatically.

The sensitivity should be the found laser amplification.

Now you have entered all desired values. Press “Auto TPID” to start the iteration and wait until the “Auto TPID”-button is solid black again. The simulator now tries to find the best settings corresponding to your initial parameters. You can use these parameters in the laser control settings window and maybe adjust them a bit to optimize your feedback loop.

If the controller does not work properly with the found parameters, you might need to repeat the procedure with slightly different initial values. The better you know your conditions and the laser properties, the better are the estimated values.

If you change the formula in your laser control settings, you need to use the same formula in the simulator and run it again!

We are always open for customer requests and happy to support you to find a quick and satisfactory solution.